Contents

- 1Introduction

- 1.1Packaging and accessories

- 2Connectors & cabling

- 2.1Casing & cooling

- 3Input filtering

- 4Primary side

- 4.1+5 V stand-by rail

- 5Secondary side

- 5.1Build quality

- 6Load testing

- 6.1Loading +5 V SB

- 6.2Combined loading

- 6.3Combined loading ripple

- 6.4Crossloading, overloading

- 6.5Crossloading, overloading ripple

- 7Conclusion and evaluation

- 7.1Thanks

Secondary side

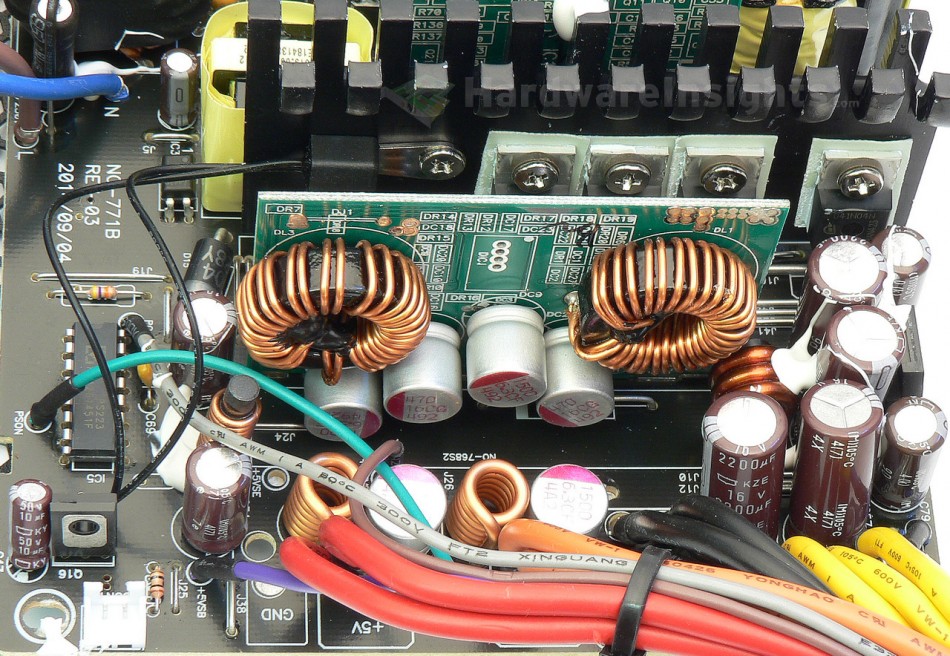

The active (synchronous) rectification in the Silverstone Strider Gold S is handled by two pairs of Infineon IPP041N04N G (80/400 A at 25 °C and 40 V, Rds(On) 4.1 mΩ at 80 A and 25 °C) transistors in TO-220 package, all mounted on common secondary heatsink. The output is filtered by two NCC KZE 2200/16 caps before Pi coil and two more after Pi coil. Both the DC-DC modules are housed on a single daughterboard with Anpec APW7159 buck PWM controller driving two pairs of Infineon IPD060N03L G (50/350 A at 25 °C and 30 V, Rds(On) 9 mΩ at 30 A and 4.5 V Vgs) transistors in TO-252 package per each module (8 transistors together). The modules have a single 470/16 polymer looking like Enesol Enecap for extra +12 V filtration and 1500/6.3 for output directly on the daughterboard, with one more per rail on the mainboard (after Pi coil). The −12 V rail has a single KY 470/25 for lower voltage feeding the KIA7912PI regulator and 1000/16 for filtration of the higher output. Thanks to this I expect very tight and low-ripple −12 V output.

As this unit is fully modular, all the power is conducted with a few 14AWG wires to another board holding the connectors. There are a few extra Chemi-Con polymer capacitors, PSF 330/16 for +12 V and PSE 560/6.3 for minor rails. A Silicon Touch Technology chip, the usual PS223, is used for UVP, OVP, OTP, some OCP and also generating Power Good signal/turning on the unit. Thermistor for fan speed control and OTP is firmly screwed to the secondary heatsink.

Build quality

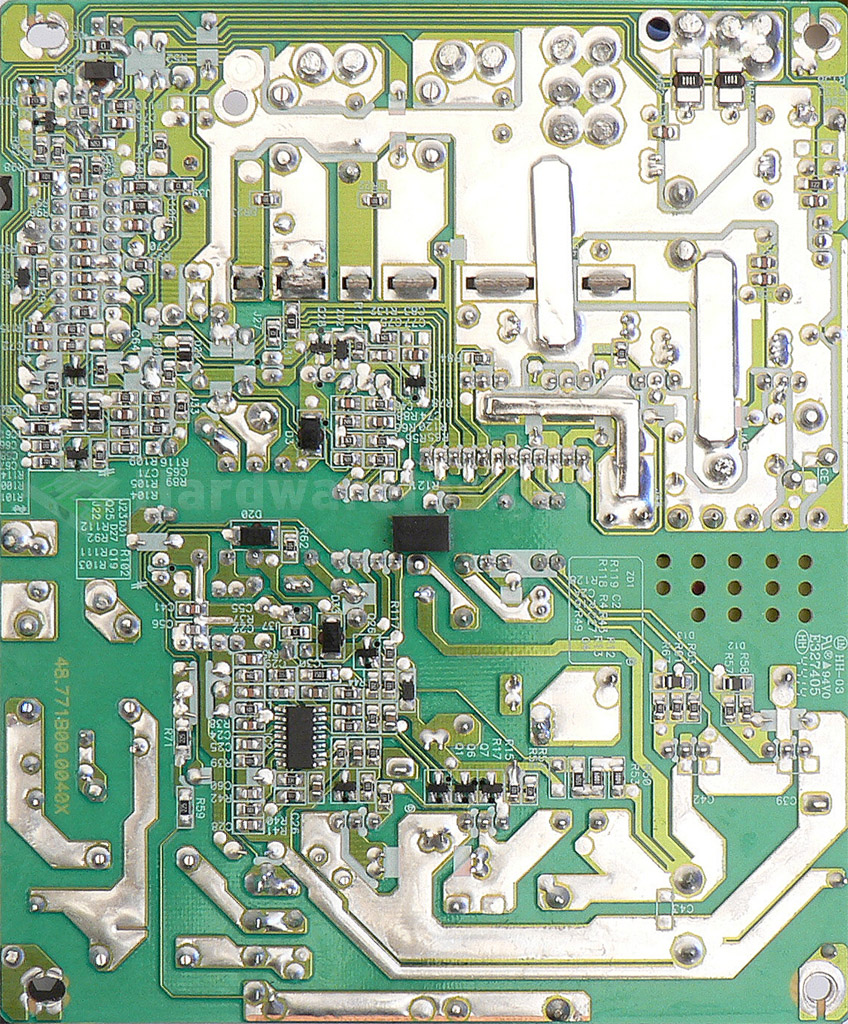

As usual I will focus on the overall build quality and other things like electrical safety here as the quality of the components used was already discussed before. Thermistor is not present at all, varistor is not sleeved while sandwiched between components, that is not good. However, filtration coils are insulated with heatshrink. Otherwise there is enough room between components so no problem here. Primary and secondary side separation is good with some extra drilling under the main transformer. Almost all electrodes are very precisely cut. I found only one manual repair and what’s positive, no dirt or solder flux residue.

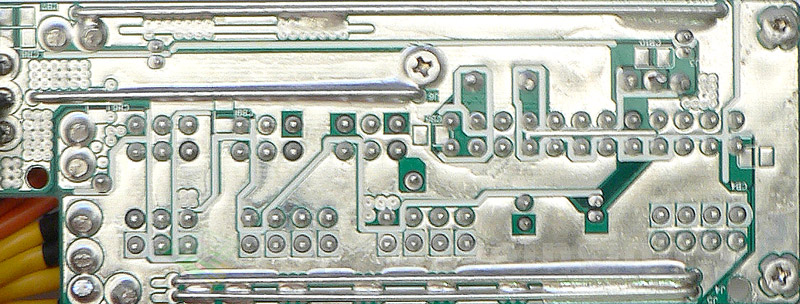

On the other hand, there were many solder balls, I stopped counting after like 20 so I think taking 20 points would be adequate. Sirtec should consider some more brushing of the soldering side to clean all those balls, those are very dangerous if they get loose and short something. Also, one of the ground wires got loose when I moved the modular connnector board, obviously there was not enough solder on this joint. Conductive paths reinforcement, on the other hand, is very good with layers of extra solder and also metal plates or wire jumpers on paths conducting very high currents.