Contents

- 1Introducing the Spire Jewel 350 W (SP-ATX-350WT-PFC)

- 1.1Packaging and accessories

- 2Connectors & cabling

- 2.1Casing & cooling

- 3Input filtering

- 4Primary side

- 4.1+5 V stand-by rail

- 5Secondary side

- 5.1Build quality

- 6Load testing

- 6.1Loading +5 V SB

- 6.2Hold-up time

- 6.3Combined loading

- 6.4Combined loading ripple

- 6.5Crossloading, overloading

- 6.6Crossloading, overloading ripple

- 6.7Fan speed, temperatures and noise

- 7Conclusion and evaluation

- 7.1Thanks

- 7.2Discussion

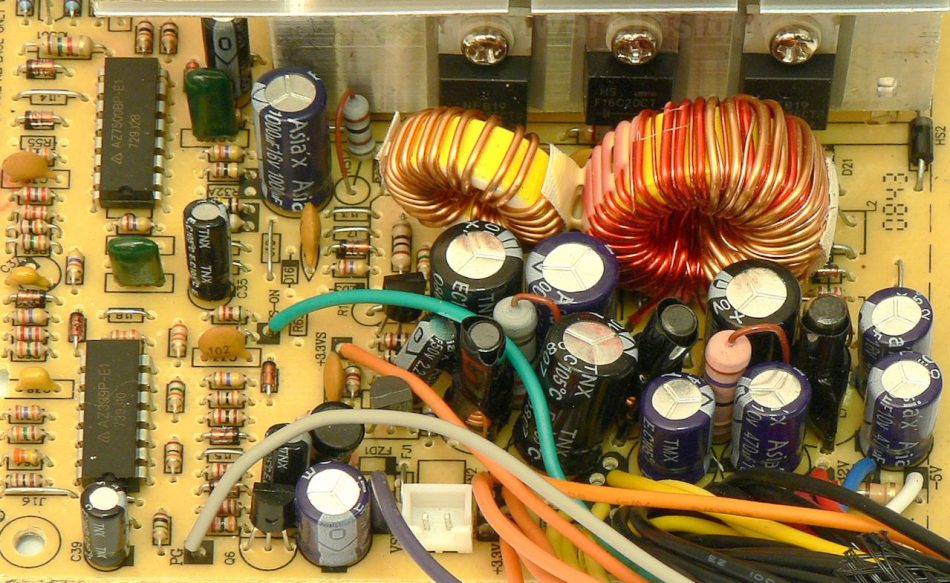

Secondary side

The secondary side of the SP-ATX-350WT-PFC uses standard set: Schottky rectifiers for +5 V and +3.3 V rails, fast recovery for +12 V. The +3.3 V is generated from +5 V winding using magnetic amplifier, the −12 V from +12V transformer tap and the −5 V similarly from +5 V transformer tap. The rectifiers for both minor positive rails are MBR2045CTG (20/150 A at 45 V, drop of 0.72 V at 20 A and 125 °C, 0.84 V at 25 °C) in TO-220 package. That is especially funny when the rated output of +5 V rail is 25 A. The +12 V rectifier is then F16C20C (16/150 A at 200 V and 125 °C, drop of 1.3 V at 8 A and 25 °C) also in TO-220. The losses only here on the rectifiers will be up to about 40 W if the unit manages to deliver the power in the first place, which I doubt.

It even has full Pi filters on all main rails, which is nice for the current price, but it won’t save the day. The caps are Asia’X again and mostly just combination of 1000 and 470μF. Though it is worth mentioning that the last gutless wonder (Whitenergy ATX-350W) somehow managed to deliver power with spec on ripple so we will have to see. The box lies about fan control as the fan-controlling reference is not present and the fan header is hard-connected to +12 V. As secondary monitor there is the AZ339-P aka LM339 comparator, I think the best we will get from it is short-circuit protection. But lets keep the hope, maybe it will turn off instead of exploding.

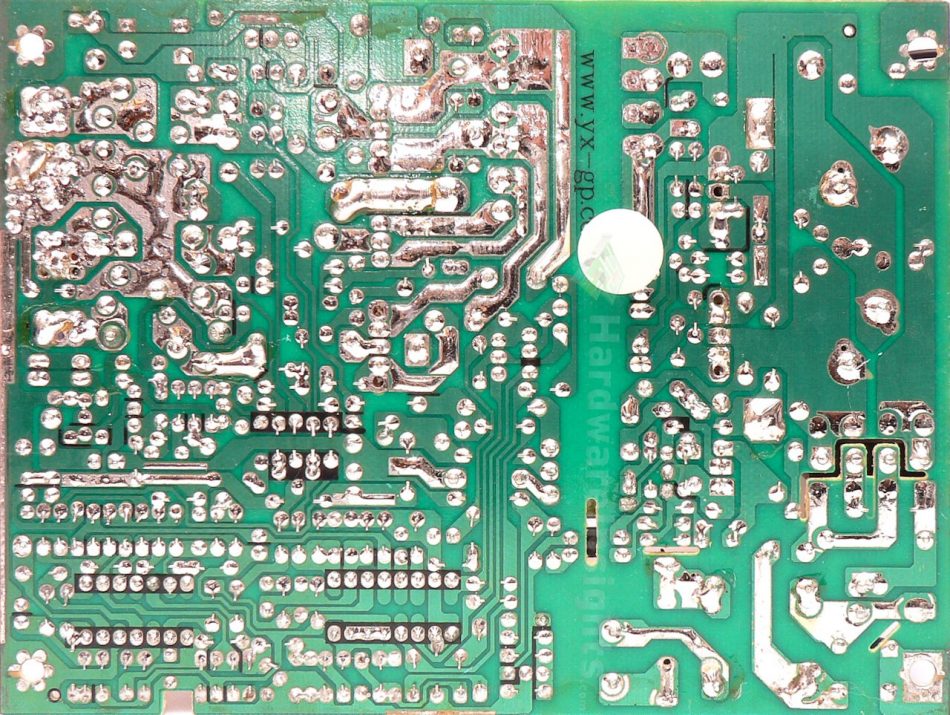

Build quality

As usual, I’ll focus on the overall build quality and other things like electrical safety here, as the quality of the components that were used was already discussed before. The separation between the primary and secondary sides is good, there are even some extra creepage slots under the optocoupler and between the bridge rectifier electrodes. That’s it, no varistor, no thermistor, not safety-certified Y caps. On top of that, hard chloroprene glue over primary side components. Only good thing is the insulation film under the board and also the plastic spacer. I guess to keep the board from touching the casing as it softens and bends as the unit heats up.

The electrodes are trimmed OK. But the soldering is bad, both wave-soldering and then manual soldering of the cables. Many joints hardly have any solder in them and barely have conductive path. That includes the primary transistors. The paths are reinforced which is not that bad, but there are some solder balls, I found about five. One of the primary capacitors had its sleeve burned through because of soldering iron. Most likely somebody touched it and some solder remained in there as it cooled and hardened. Man…get it out of my sight. I don’t even want to count the points for this, does anybody expect it will pass??