Contents

- 1Introducing the Zalman ZM600-LX

- 1.1Packaging and accessories

- 2Connectors & cabling

- 2.1Casing & cooling

- 3Input filtering

- 4Primary side

- 4.1+5 V stand-by rail

- 5Secondary side

- 5.1Build quality

- 6Load testing

- 6.1Loading +5 V SB

- 6.2Hold-up time

- 6.3Combined loading

- 6.4Combined loading ripple

- 6.5Crossloading, overloading

- 6.6Crossloading, overloading ripple

- 6.7Fan speed, temperatures and noise

- 7Conclusion and evaluation

- 7.1Bonus

- 7.2Thanks

- 7.3Discussion

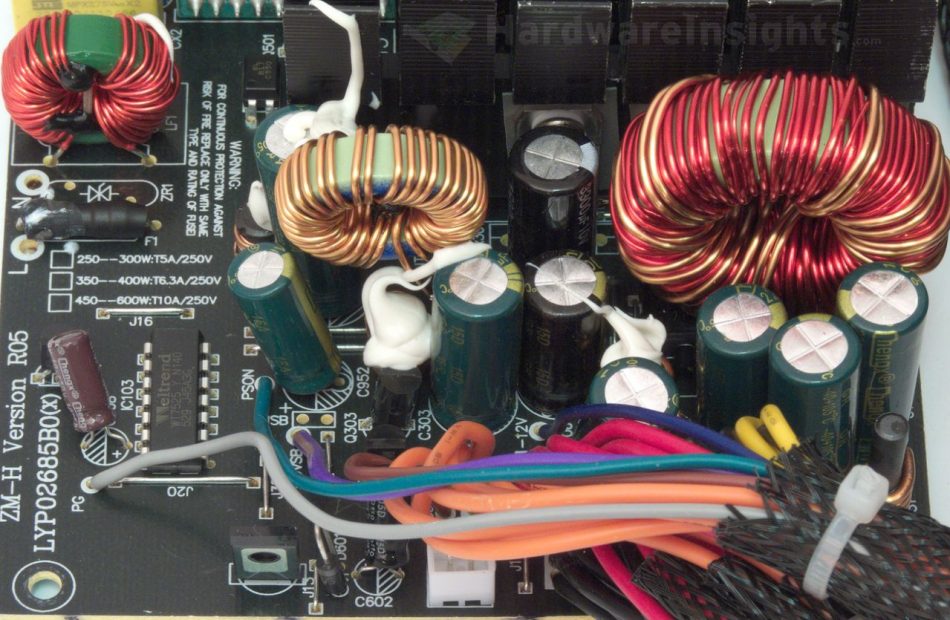

Secondary side

On the secondary side of the ZM600-LX we can observe the usual scenery: a +3.3 V magamp and a couple of TO-220 Schottky rectifiers. There are two MBR30100CT (30/250 A at 100 V and 100 °C, drop of 0.85 V at 15 A and 25 °C, 0.78 V at 125 °C) in parallel for the +12 V. For the +5 V there are also two rectifiers in parallel, the ST Micro STPS2045CTC (20/180 A at 45 V and 155 °C, 0.84 V at 25 °C and 20 A). The +3.3V rail only has a single STPS3045CT (30/220 A at 45 V and 155 °C, 0.84 at 30 A and 25 °C). All these semiconductors use the same common secondary side heatsink. A small thermistor probe which provides driving for the fan controller sits under it. A 2SB772 PNP transistor functions as the linear regulator for the fan.

As for the filtering, the ZM600-LX has more ChengX GR caps. There is 2200/16 for the +12 V, and 2200/10 with 1000/10 for the +5 V. On the +3.3 V rail there is one Nicon KME 3300/10 (never heard of this brand before) with a ChengX GR 2200/10. The −12 V rail has another GR, 1000/16 but with black sleeving. The DIP-14 Weltrend WT7525 acts as a secondary supervisor, providing UVP, OVP and OCP. And as usual it also monitors PWR On signal and provides PWR Good. It supports two +12V OCP channels (with an extra resistor divider and also utilising the UVP channels). This unit claims to only have a single rail and indeed there is only a single current shunt leading to the first rail. Rail B is then connected to A via a wire jumper.

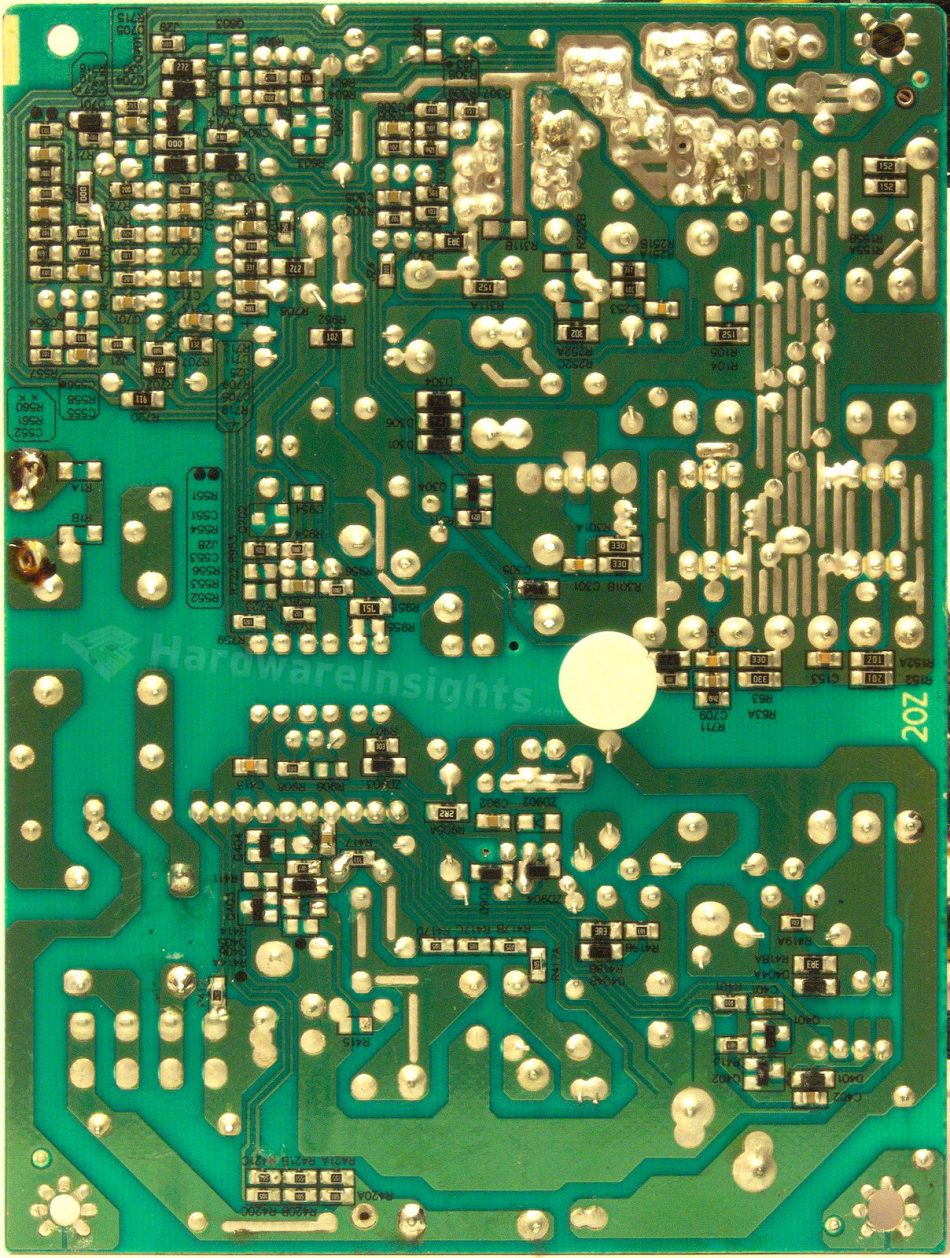

Build quality

As usual, I’ll focus on the overall build quality and other things like electrical safety here, as the quality of the components in use was already discussed before. The separation between the primary and secondary sides is good. Not only is there an insulative film under the board, but also a plastic spacer. Many of the leads were trimmed quite poorly and kept long, and this is something which I’d like to see them improve upon. Besides missing both the thermistor and varistor, the insulation of the components present seems OK. Hui Cheng used the proper type silicone in still reasonable quantities.

The paths on the secondary side are also reinforced with some extra layers of solder. The soldering is not the worst but could definitely improve. It seems that the solder bath was very hot and the unit was cooled too fast as to not allow the solder to solidify properly. There are also a few joints which could seriously use touching up. Those which have been resoldered have not been cleaned, leaving both solder and soldering flux residue. Besides that, I also found a few tiny solder balls, but most importantly one very big one, approx. 2mm in diameter. It was also not held firmly in place which is a real danger as it could have moved, shorting something inside the unit. For that I will deduct two points.