Contents

- 1Introduction

- 1.1Packaging and accessories

- 2Connectors & cabling

- 2.1Casing & cooling

- 3Input filtering

- 4Primary side

- 4.1+5 V stand-by rail

- 5Secondary side

- 5.1Build quality

- 6Load testing

- 6.1Loading +5 V SB

- 6.2Voltage hold-up time

- 6.3Combined loading

- 6.4Combined loading ripple

- 6.5Crossloading, overloading

- 6.6Crossloading, overloading ripple

- 7Conclusion and evaluation

- 7.1Thanks

- 7.2Discussion

Secondary side

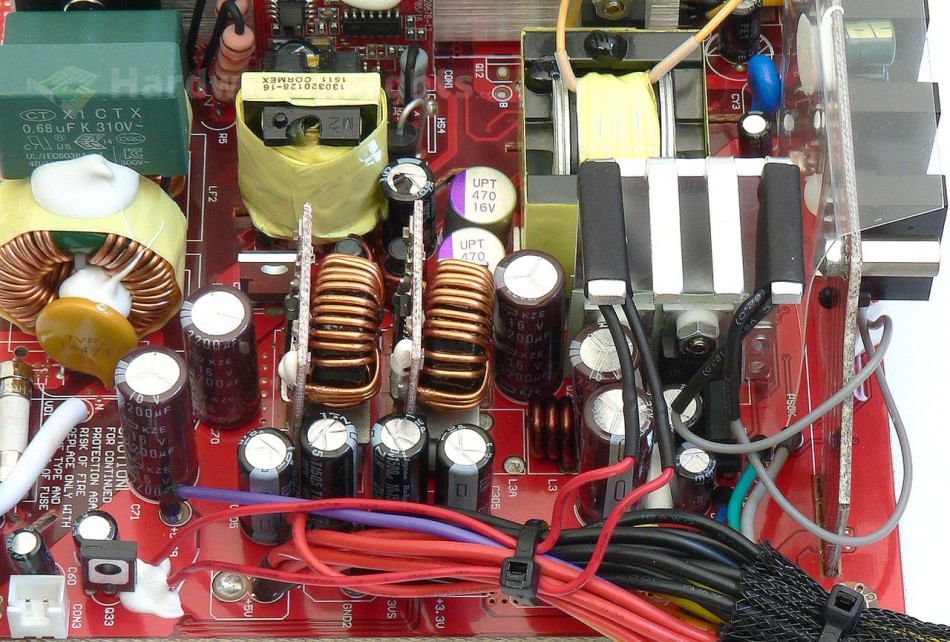

One thing I especially like about this unit is how small components it uses. The main transformer is tiny and the secondary rectifying transistors have only a tiny heatsink. The DC-DC modules are tiny too. Thanks to that the unit is quite airy and only requires slow fan without any strange foil covers etc. for cooling. Two pairs of Infineon IPP041N04N G (80/400 A at 25 °C a 40 V, Rds(On) 4.1 mΩ at 80 A) transistors in TO-220 package are used. If they had slightly bigger heatsink I think the unit could very well be semi-passive. The Champion Micro CM6901TX controller is used for driving both primary and secondary transistors.

Three Chemi-Con KZE 2200/16 capacitors are used to smooth the +12 V together with two 470/16 polymers. Two more 330/16 polymers are on the input side of the two DC-DC modules (so four of them alltogether). That is 6.6 and 2.26 mF just on +12 V rail! DC-DC modules are very small, each on separate board and use only one ICs each which I thought were MOSFETs back in 2013 but actually are Texas Instruments CSD86350Q5D Buck NexFET power blocks for up to 40 A each. (Enhance is also using them in the Silverstone SFX Series 450 W.) Both are controlled by Anpec APW7073 drivers. Output is filtered by another 330/16 polymer and two pairs of Rubycon ZLH 1500/10 capacitors. The −12 V rail has ST Micro L7912CV voltage regulator to higher low negative voltage to stabilised −12 V output and uses Rubycon YXG 220/25 on the input and 100/25 on the output.

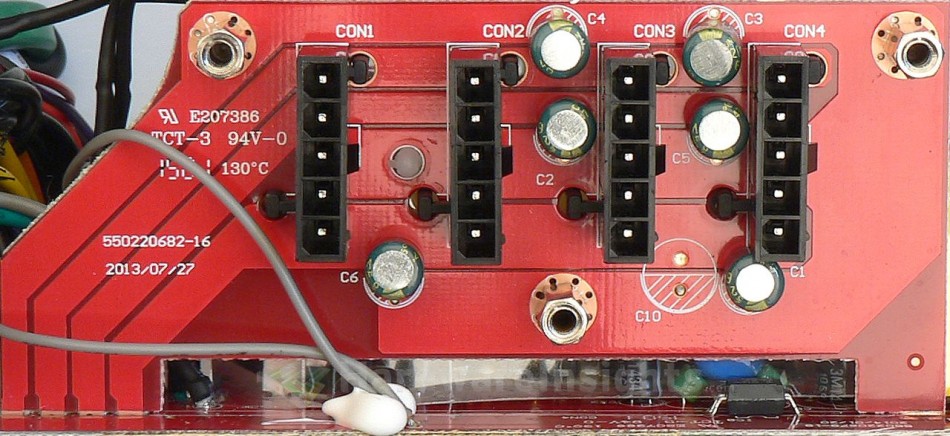

Daughterboard carrying modular connectors is hard soldered into the main board and also has two extra Suncon Sunelec 220/25 capacitors per each rail (+3.3, +5 and +12 V). A Silicon Touch PS223 monitor is used for the protections (OVP, UVP, OCP and OTP) and turning the PSU on while also generating Power Good signal. There are two thermistors on the secondary heatsink, one for fan speed and second for OTP. Fan controller uses an ordinary TO-126 transistor and two Rubycon capacitors.

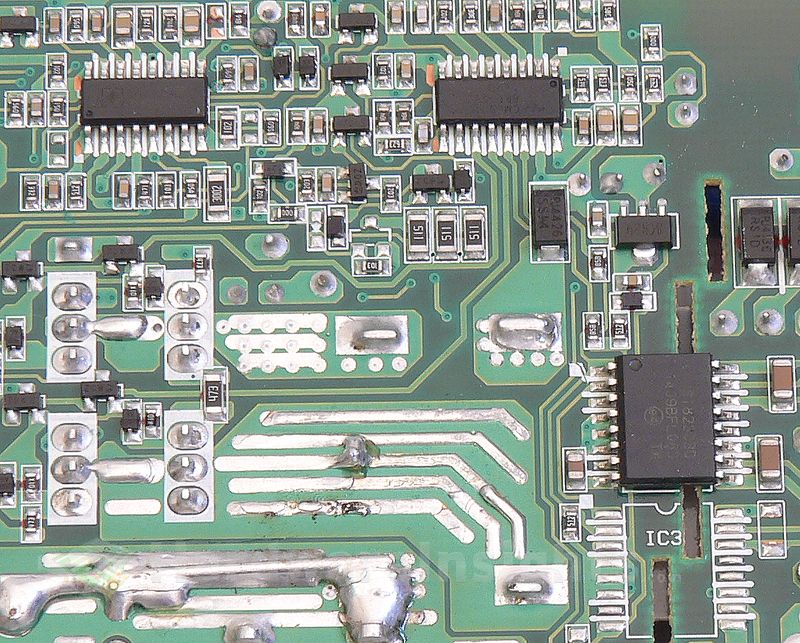

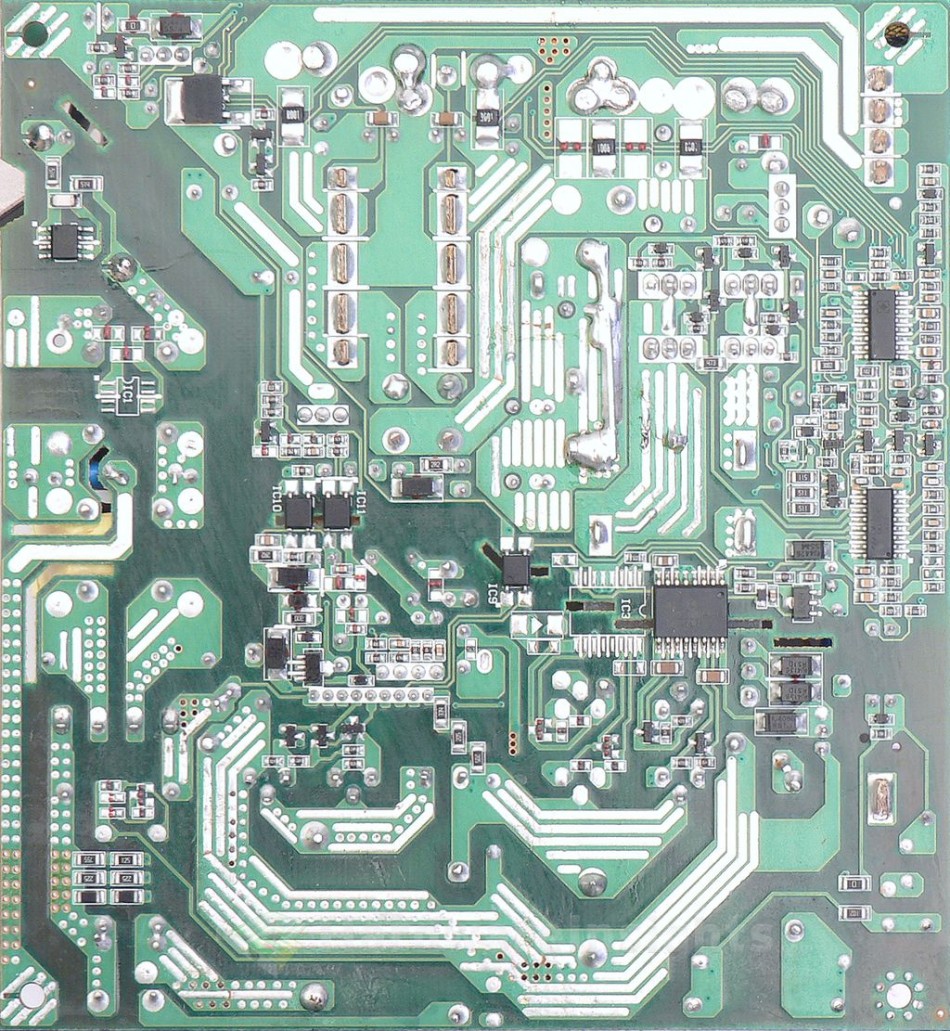

Build quality

As usual I will focus on the overall build quality and other things like electrical safety here as the quality of the components used was already discussed before. Both thermistor and varistor are not sleeved while sandwiched between components. However, filtration coils are insulated with some tape at least. There is enough room between components so no problem here. Primary and secondary side separation is good with much extra drilling under the main transformer, optocouplers and input filtration components. Most electrodes are precisely cut. There is some manual (re)soldering, it is a messy job with solder and flux residue all around.

Because of that I found about 30 solder balls (many of them tiny though so I count them as half) all over the board. That’s unbelievable! Any one of them may get loose, short something somewhere and make the unit go KABOOM! Part of the copper layer on the very top (image above) does not even have solder on it. This is really SO messy, clearly Enhance does not care much about cleaning these high-end units. There are nicely reinforced conductive paths though in many places the wave soldering is not good. For such terrible cleaning I think 25 points down is fair for sure.