Contents

- 1Introducing the Super Flower Leadex Platinum 750 W

- 1.1Packaging and accessories

- 2Connectors & cabling

- 2.1Casing & cooling

- 3Input filtering

- 4Primary side

- 4.1+5 V stand-by rail

- 5Secondary side

- 5.1Build quality

- 6Load testing

- 6.1Loading +5 V SB

- 6.2Voltage hold-up time

- 6.3Combined loading

- 6.4Combined loading ripple

- 6.5Crossloading, overloading

- 6.6Crossloading, overloading ripple

- 6.7Fan speed, temperatures and noise

- 7Conclusion and evaluation

- 7.1Thanks

- 7.2Discussion

Secondary side

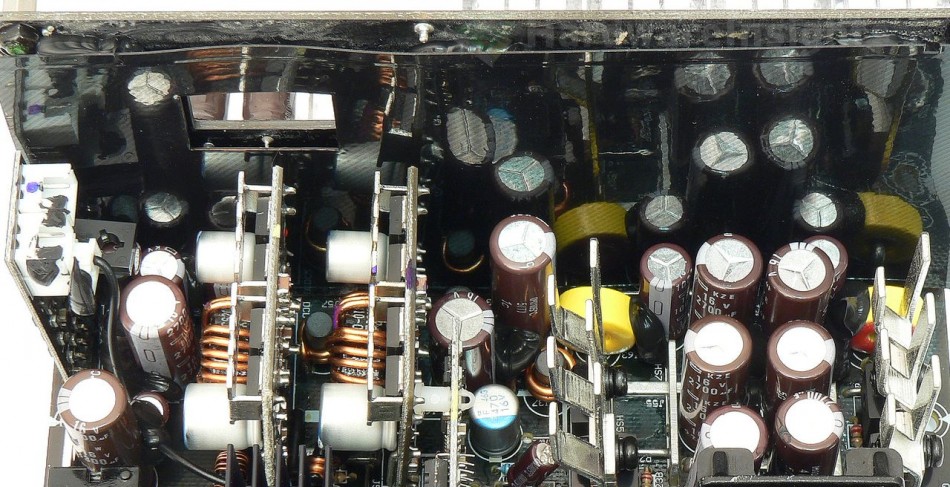

Two groups of transistors are responsible for the synchronous rectification in this units. Each group consists of three Infineon IPP041N04N transistors (80/400 A at 40 V and 25 °C, Rds(On) 4.1 mΩ) in TO-220 package, each group having its own copper heatsink. The +12 V filtering is quite heavy. First, we have six NCC KZE 2700/16 capacitors in front of two inductors and then single KY 1000/16 after each inductor. The feed for DC-DC modules has a separate Pi filter with one extra NCC PSF 470/16 polymer, plus there is one more on each module directly. A KY 220/16 capacitor is used for the −12 V rail.

There are two separate DC-DC converter modules with two pairs of Infineon IPD060N03L G (50/350 A at 30 V and 25 °C, Rds(On) 9 mΩ at 30 A and Vgs of 4.5 V, 6 mΩ at 10 V) transistor each. They come in TO-252 package and have small copper heatsinks hovering over them. There is also a buck controller on each, the On Semi NCP1587. Each module has another PSF 470/16 on the output (but smaller than on the input). The +3.3 V rail then has two KZE 2700/16 in its Pi filter (each one of different height), the +5 V uses single 2700 and single KY 1000/16. As for the fan control, small board on the left side is responsible for this purpose, using 2SB772 (−3/−7 A at −40 V) PNP transistor in TO-126 package and also On Semi LM324ADG operational amplifier. As for the secondary supervisor, the AA9013 microchips seems to also be responsible for this purpose with another such opamp.

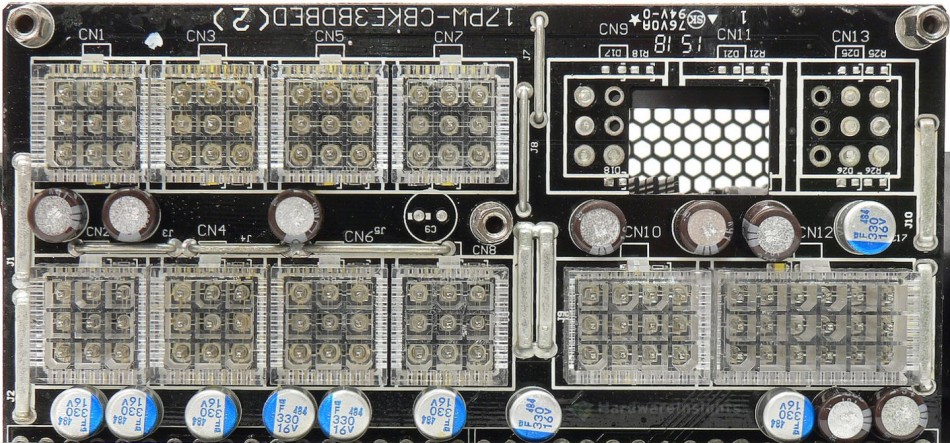

The modular board is soldered by 36 thick leads to the main board. There seem to be two white SMD LEDs under each connector which glow when connector is plugged in. This is also the reason behind using 9pin connectors (one pin than backfeeds the diodes). I think this is nice gadget, let’s give half an extra point for that. There are many more NCC PSF 330/16 polymers and KRG 330/16 wet electrolytics on this board alone. I am not exactly sure which capacitor filters which rail, however, it is sure that most of them are used for the +12 V rail and only couple of them filter other rails; at least KRG seems to filter −12 V and one the stand-by rail. Furthermore capacitors are soldered directly on the modular cabling, close to their further connectors! Those are only CapXon KM 220/16 though (standard with 2000 hours life), but I think they will not see much ripple so they will most likely be alright.

Build quality

As usual, I’ll focus on the overall build quality and other things like electrical safety here, as the quality of the components that were used was already discussed before. The separation between the primary and secondary sides is good, and we also have some extra holes that were drilled under the main transformer for extra cooling. The thermistor is sleeved with heatshrink (even though it is bypassed by a relay) while varistor is not. I would say that overall the insulation is good. There are three rubber pads on the bottom of the board (to prevent it from bending – as it is quite heavy). Also there is insulated copper foil between the modular board and the secondary side components to shield the output from EMI. Conductive paths are reinforced by thick layers of solder, and part of the +12 V path is even reinforced with copper plate. Thick strips of copper are used to conduct most of the currents on the secondary side.

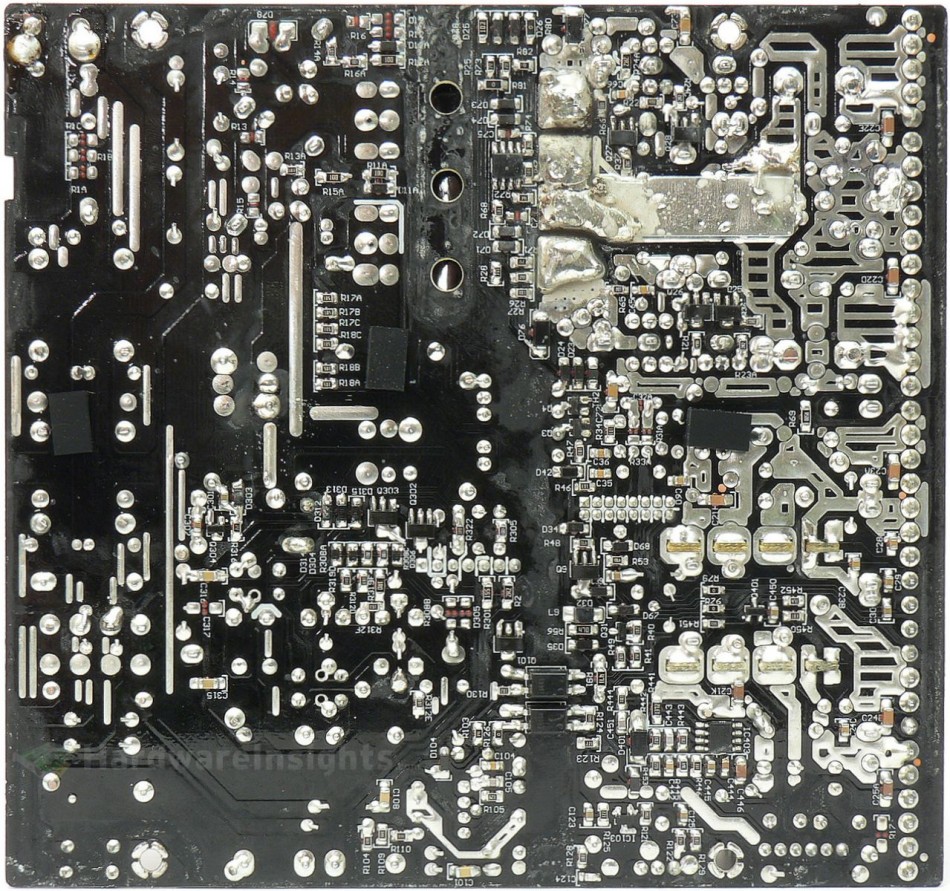

Overall, I would say the upper part of the unit seems very nice and clean, but the soldering side is much worse. The wave soldering quality itself is worse than I would like, but that can still do. But after the resoldering of couple joints and adding great amounts of solder to many more, nobody cleaned the board properly afterwards! I also found four solder balls. It is said that Super Flower can not keep up with orders and they outsource. I do not think they would outsource such a high-end unit elsewhere and they continue to make these units in-house, but clearly they somewhat sacrificed on product quality for quantity. I think that for such number of so messy manual resoldering jobs (and the solder balls), minus ten points is the bare minimum.

But there is one more thing I must deduct one further point for – you can notice yourself: there is O-ring rubber sealing sitting between the fins of the PFC heatsink! Fortunately it is not conductive, but still there is something wrong about leaving moving parts laying inside power supply!