Contents

- 1Introduction

- 1.1Packaging and accessories

- 2Connectors & cabling

- 2.1Casing & cooling

- 3Input filtering

- 4Primary side

- 4.1+5 V stand-by rail

- 5Secondary side

- 5.1Build quality

- 6Load testing

- 6.1Loading +5 V SB

- 6.2Voltage hold-up time

- 6.3Combined loading

- 6.4Combined loading ripple

- 6.5Crossloading, overloading

- 6.6Crossloading, overloading ripple

- 7Conclusion and evaluation

- 7.1Thanks

- 7.2Discussion

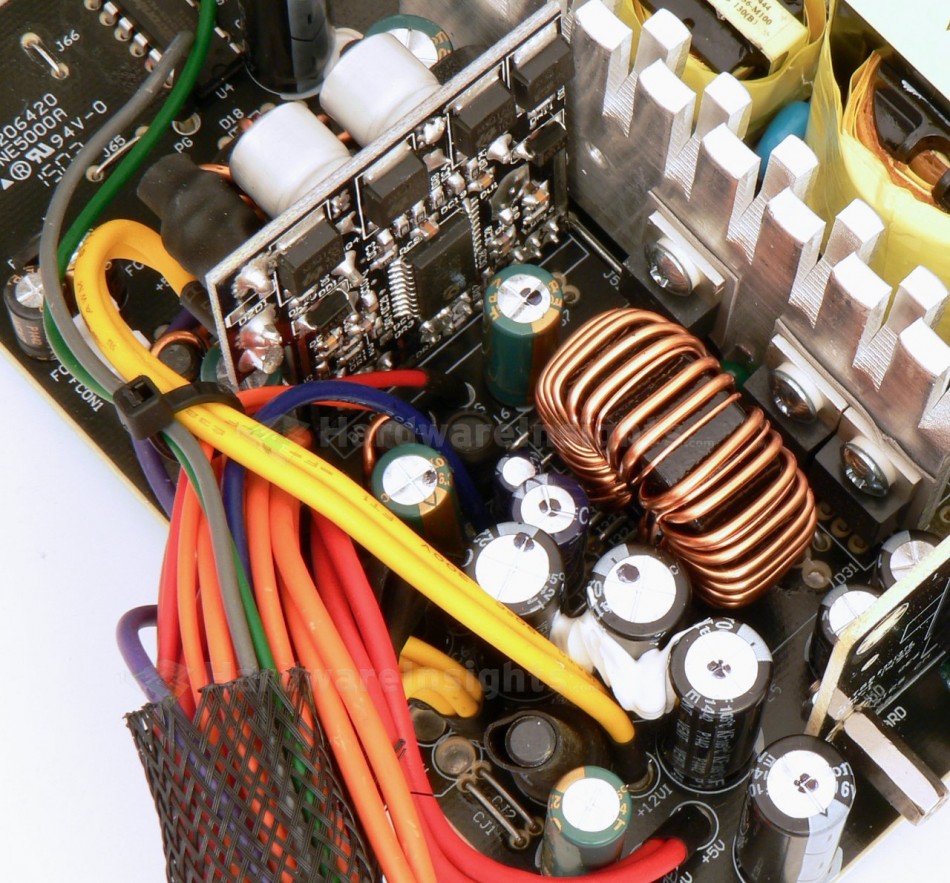

Secondary side

The rectification here is quite interesting. There is a single PFC Device Corporation PFR40V60CT rectifier (40/400 A at 150 °C and 60 V, drop of 0.55 V at 20 A and 25 °C). Parallel to that, there are two SG65N02P transistors (no information available, however, considering this is just Chinese copy of ON Semiconductor NTB65N02R or something similar, it is 65 A at 24 V), everything in TO-220 package mounted on common secondary heatsink. Both the DC-DC modules are on single daughterboard with two pairs of Ubiq Semiconductor Corporation QM3016D transistors (96/192 A at 25 °C and 30 V, Rds(On) 4 mΩ at 30 A and Vgs of 10 V or 6 mΩ at 4.5 V) in TO-252 package per rail. Anpec APW7159 is used as a driver.

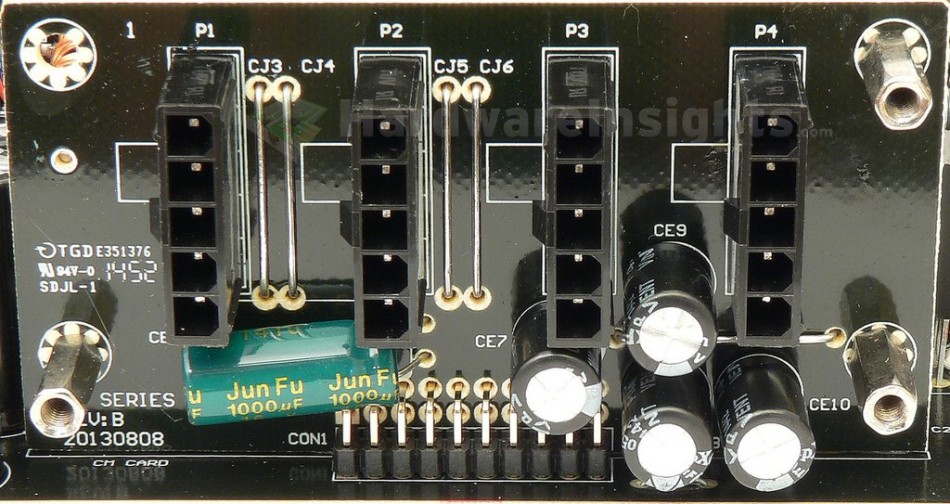

Four C(r)apXon 2200/16 capacitors are used to filter the +12 V rail directly, one more JunFu 1000/16 is on the modular board and two CapXon 470/16 polymers are on the DC-DC board input. Two C(r)apXon GF 2200/6.3 caps are there for +3.3 and +5 V output with two more KF 1000/6.3 for +5 V and one GF 2200/6.3 for +3.3 on the path to the modular board. Also there are even two more KF 1000/6.3 per each rail on the modular board itself. That makes 8.4 and 8.6 mF altogether for +5 V and +3.3 V respectively.

A SYNC Power microchip is used as the synchronous rectification controller, the SP6019. Then there is also LM339 comparator most likely to drive the fan and also provide information for OTP as there is only one thermistor, barely touching the heatsink without any thermal grease. The Sitronix ST9S429-PG14 monitor is used as supervisor for OVP, UVP, OCP and OTP.

Build quality

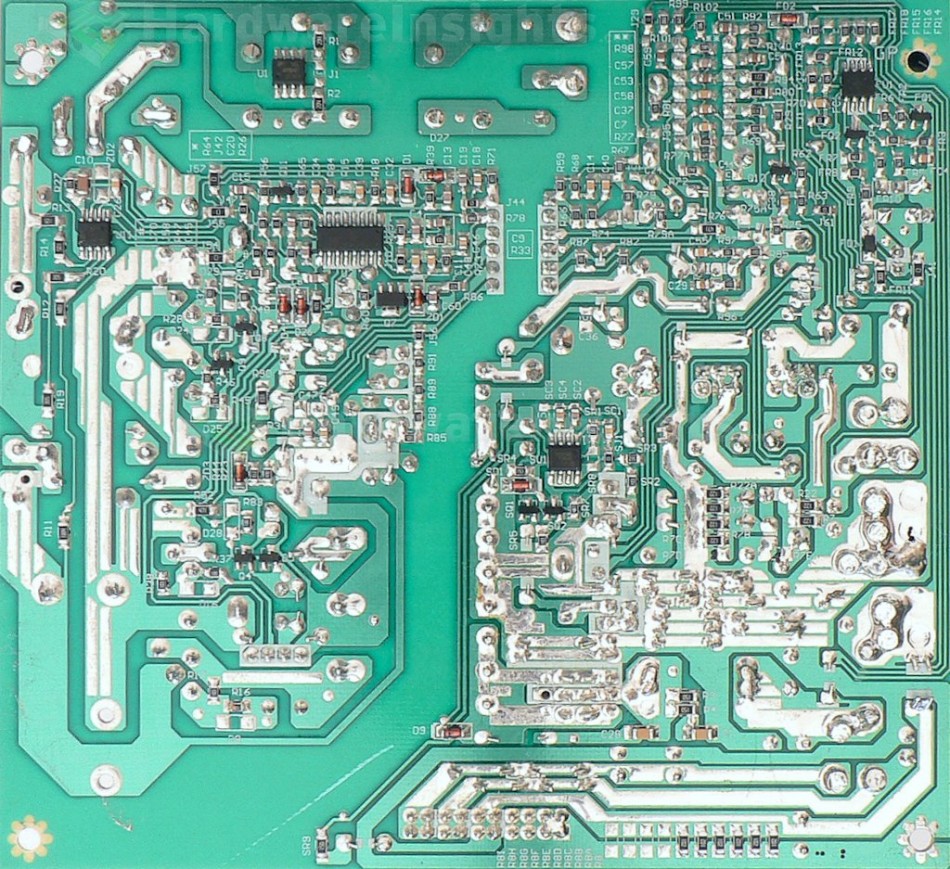

As usual I will focus on the overall build quality and other things like electrical safety here as the quality of the components used was already discussed before. Besides the first thermistor and varistor, nothing is sleeved with heatshrink or insulated by any other means. Components have enough room though, primary and secondary side separation is good. One major problem is a strip of copper wire which is being held in thermal compound on one PFC transistor, it is actually visible on the image in previous chapter. This is very dangerous as the wire may get loose (when the compound softens with high temperature) and short something. Two points down!

Soldering looks good on the first look, on the second one there are some solder remains. There does not seem to be any manual repairs, on the other hand electrodes could be cut better, often they are bent so they almost touch each other. Paths especially on secondary side are heavily reinforced with solder and wire jumpers. I found about ten solder balls (few tiny are counted as one whole) and a couple joints which may form cold joints in future. I think it is 13 points down.