Contents

- 1Introducing the Silverstone Strider Titanium 600 W (SST-ST60F-TI)

- 1.1Packaging and accessories

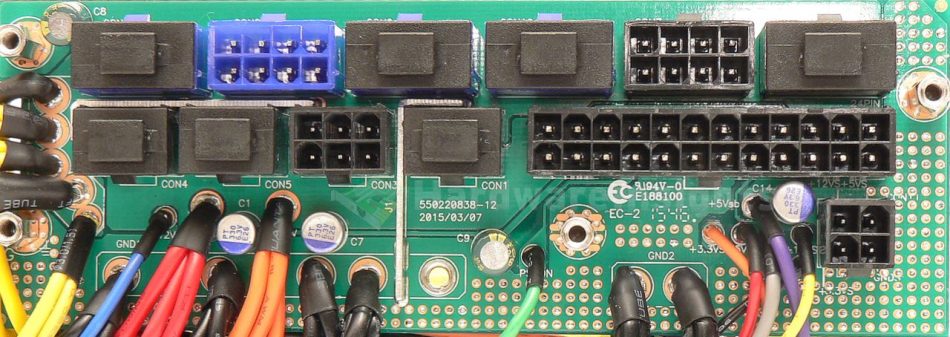

- 2Connectors & cabling

- 2.1Casing & cooling

- 3Input filtering

- 4Primary side

- 4.1+5 V stand-by rail

- 5Secondary side

- 5.1Build quality

- 6Load testing

- 6.1Loading +5 V SB

- 6.2Hold-up time

- 6.3Combined loading

- 6.4Combined loading ripple

- 6.5Crossloading, overloading

- 6.6Crossloading, overloading ripple

- 6.7Fan speed, temperatures and noise

- 7Conclusion and evaluation

- 7.1Thanks

- 7.2Discussion

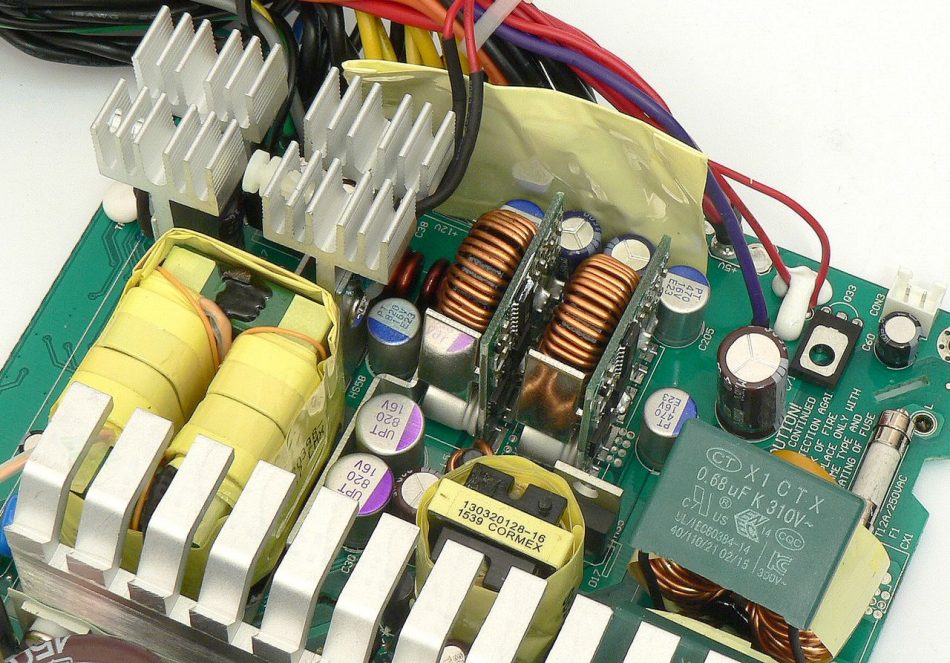

Secondary side

The secondary side of the SST-ST60F-TI carries the rectification transistors, two blocks of four pieces each. Those are Infineon BSC026N04LS (100/400 A at 25 °C and 40 V, RDS(On) 2.6 mΩ at 50 A and VGS of 10 V, 3.6 Ω at 4.5 V) in the PG-TDSON-8 package (also known as HSON, LFPAK, DFN5x6-8). They are soldered on the bottom, and there are copper plates which go through routed slots and soldered onto the large traces. These copper plates are then in turn screwed into aluminium heatsinks on the top side of the PSU. There’s also a silicone pad that thermally couples the transistors to the PSU chassis, thus helping to dissipate the heat. The output is filtered by two Unicon UPT 820/16 polymers (this is a Japanese brand I’ve never heard about before), one CapXon PT 820/16 polymer, a single NCC KY 1000/16 wet electrolytic and also a KZE 2200/16.

The DC-DC modules for generating +3.3/+5 V rails use a tiny board for each rail with two Infineon BSC018NE2LS (100/400 A at 25 °C and 25 V, RDS(On) 1.8 mΩ at 30 A and VGS of 10 V, 2.3 mΩ at 4.5 V) transistors in a PG-TDSON-8 package each. They use small pieces of copper plates as heatsinks. Each module has its own PWM converter, the Anpec APW7073, which also monitors UVP and OCP on its own in each case. There are three CapXon PT 330/16 polymers on each module, two for extra filtering of the input (+12 V), and one for the output. Plus there is an additional single PT 470/16 and custom-size Chemi-Con LXZ 1500/6.3 on the main board as additional filtering for both the +3.3 and +5 V rails. The −12V rail uses an ordinary 7912 linear regulator with a Rubycon input cap and a Chemi-Con on the output.

If we move to the modular board, which is connected by 16AWG wires mostly, we can see there are some capacitors for additional filtering. One PT 330/16 polymer for +3.3, +5 and +5 V SB rails and some Suncon Sunelec 220/16 wet electrolytics of an unknown series, one for the +12 V, one for −12 V. The supervisor IC in the SST-ST60F-TI is the usual Silicon Touch Technology PS223, which among other things also monitors each rail’s OCP and also OTP. For that it has a thermistor probe screwed to first secondary heatsink. To the second heatsink, there’s another thermistor that is attached, but this time to provide a measurement for the fan controller, which is a Unisonic Technologies 2SB772 PNP transistor (−3/−7 A at −40 V).

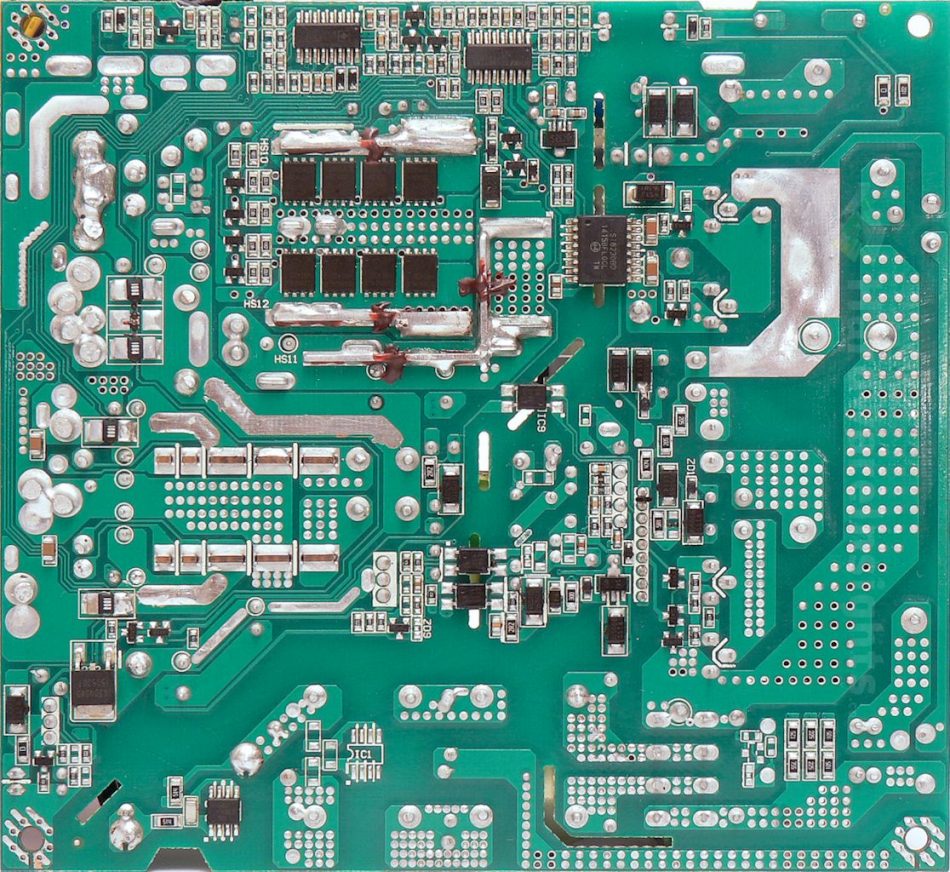

Build quality

As usual, I’ll focus on the overall build quality and other things like electrical safety here, as the quality of the components that were used was already discussed before. The separation between the primary and secondary sides is good and there are a lot of drilled holes under the optocouplers and the isodriver to provide additional insulation. Neither the varistor or the thermistor are sleeved with heatshrink. But other components were well insulated, when they were close to each other at least one of them always has some extra tape or electrode/wire insulation (plastic or heatshrink tubing mostly). Under most of the transformers, there was also plastic pads for electrical insulation.

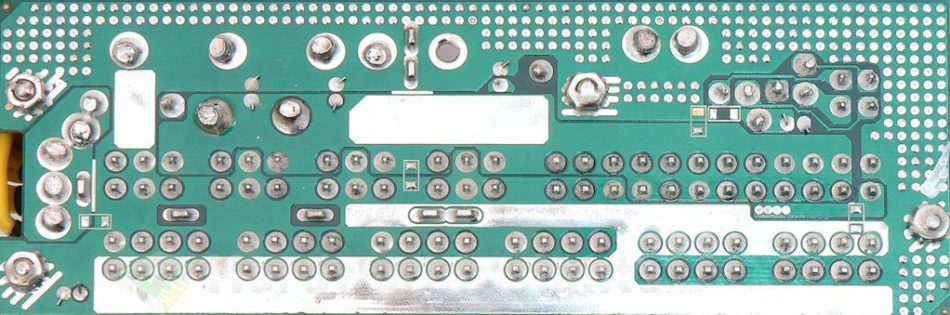

The design is nice and clean, but the wave soldering is not the best I have seen. It seems Enhance could enhance the soldering by using better soldering flux, here it seems as though it was bubbling and evaporating during the soldering process which seems to have resulted in in many holes being left in the solder after it hardened. The overall appearance of the solder makes me feel as though they used too high of a temperature and/or cooled the board down too quickly after soldering. None of the joints seem like they’re likely to crack anytime soon and it doesn’t seem like any of them will turn into cold joints, but they don’t look nice neither. Plus, the job they did cleaning the flux residue isn’t perfect – it got some attention, but it seems not enough cleaning agent was used so the residue was just smeared all over the board. It’s even sticky on many areas, so no doubt some dust will get stuck to the board. I found three tiny solder balls here.

The modular board seems cleaner, but due to all the through-board interconnects being filled with solder, there were too many solder balls. I found about 16 tiny ones, with most of them being trapped in either the solder mask or the flux residue. Both the boards use double-sided epoxy-glass PCB material which makes use of both sides of the PCB. Plus, there is some path reinforcement. But for the soldering and the balls I’ll deduct ten points. Enhance should really work on it, this board does not strike me like they do it better since the Cooler Master unit we’ve seen before.